What is a Ball Screw for Sale and How Does It Work?

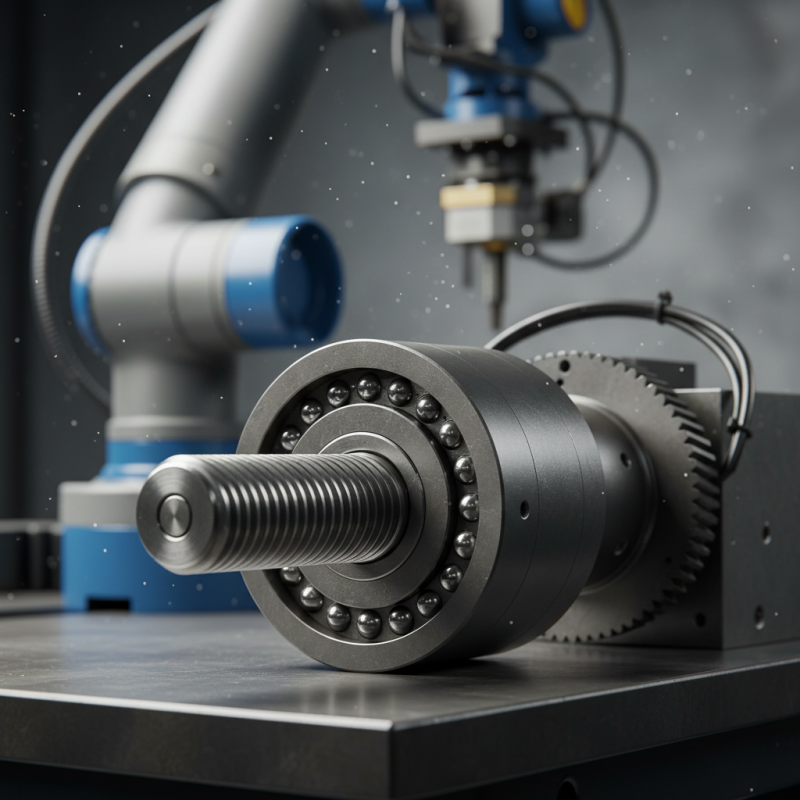

A ball screw for sale is essential in precise linear motion systems. It consists of a threaded shaft and ball bearings. This design reduces friction and enhances efficiency. Many industries rely on ball screws for automation, robotics, and CNC machinery.

When considering a ball screw for sale, it's essential to understand how it operates. The balls circulate in a recirculating nut, converting rotational motion into linear movement. This mechanism allows for high precision and repeatability in movement. Buyers often face challenges in selecting the right specifications.

Some vendors may not provide adequate information. It’s crucial to research features and materials. Common pitfalls include overestimating load capacities or underestimating maintenance needs. A careful approach ensures that the chosen ball screw meets specific applications. The right choice can make a significant difference in performance and durability.

What is a Ball Screw and Its Key Components?

A ball screw is crucial in modern machinery, providing high efficiency in linear motion. It consists of a screw shaft and a ball nut. The screw has a helical groove, allowing balls to circulate between the screw and nut. This design minimizes friction compared to traditional lead screws, enhancing performance and longevity. Research shows that a ball screw can achieve up to 90% efficiency – significantly higher than many alternatives.

Key components include the screw shaft, ball nut, and the recirculation system. The recirculation system helps maintain smooth movement. Each component plays a vital role in ensuring durability and functionality. Data from industry reports indicates that the lifespan of a ball screw can reach over 20,000 hours under optimal conditions, yet improper installation can reduce this drastically.

Tips: Always keep the ball screw clean. Contaminants can wear down the components. Regular maintenance is crucial. Using the right lubrication can enhance performance, so don't overlook this. Proper alignment is key. Misalignment can lead to increased wear and a shorter lifespan. Stay vigilant about these factors for optimal functioning.

Ball Screw Load Capacity Comparison

Understanding the Functionality of Ball Screws in Motion Control

Ball screws play a crucial role in motion control systems. They convert rotary motion into linear motion efficiently. This mechanism allows for precision in applications like robotics, CNC machines, and automation systems. Ball screws use small balls that roll between a threaded shaft and a nut. This reduces friction and enhances movement accuracy.

One of the main advantages of ball screws is their ability to handle heavy loads while maintaining speed. However, improper installation can lead to premature wear. Regular maintenance is essential to ensure longevity. Simple adjustments to alignment can make a significant difference in performance. Carbon steel materials are often used, but they can be prone to corrosion without proper protection.

Understanding the functionality of ball screws is key to optimizing their use. The threaded design allows for smooth transitions and high efficiency. Each component must work harmoniously. Mistakes in assembly can introduce backlash, affecting precision. Careful analysis of these systems can lead to improved effectiveness.

What is a Ball Screw for Sale and How Does It Work? - Understanding the Functionality of Ball Screws in Motion Control

| Feature | Description | Application | Load Capacity (kg) | Lead (mm) | Accuracy (mm) |

|---|---|---|---|---|---|

| Ball Screw Type A | Precision ball screw with high efficiency | CNC machines, 3D printers | 1000 | 5 | 0.01 |

| Ball Screw Type B | Standard ball screw suitable for general applications | Robotics, automation systems | 800 | 10 | 0.02 |

| Ball Screw Type C | High load capacity ball screw | Industrial machinery, lifts | 1500 | 12 | 0.03 |

| Ball Screw Type D | Compact design for tight spaces | Medical equipment, small devices | 500 | 4 | 0.015 |

| Ball Screw Type E | High-speed ball screw | Pick and place systems, assembly lines | 600 | 6 | 0.01 |

Industries That Utilize Ball Screws for Precision Applications

Ball screws are critical components in various industries that require precision movement. Used in manufacturing, robotics, and aerospace, they provide high accuracy and repeatability. According to a recent market analysis, the global ball screw market is projected to grow by over 5% annually. This growth reflects their increasing adoption in applications that demand tight tolerance.

In automation and robotics, ball screws facilitate efficient movement in machinery. They help transfer rotary motion into linear motion with minimal friction. This efficiency is vital in scenarios like CNC machining, where precision is crucial. The automotive industry also relies heavily on ball screws for tasks like assembly and testing. Here, accuracy can significantly affect product quality.

Tip: Regular maintenance of ball screws is essential. Even minor wear can lead to performance degradation. Check for lubrication and alignment to ensure peak efficiency.

Another sector benefiting from ball screws is the medical industry. Devices like MRI machines and surgical robots depend on these components for precise movements. However, not all applications will suit ball screws. Factors like load capacity and environmental conditions must be carefully evaluated.

Tip: Consider the specifications of your application. Choosing the wrong type can lead to inefficiencies and higher costs.

Factors to Consider When Selecting a Ball Screw for Sale

When selecting a ball screw for sale, several factors should be considered. Size is crucial. The diameter and lead must match your application. A mismatch can cause poor performance. You need to think about the load capacity too. Ensure the screw can handle the weight and forces it will encounter. Failure in this area can lead to system degradation.

Material choice can also impact performance. Different materials offer varying strengths and durability. For example, steel is often preferred for its robustness. But, other materials like aluminum may be lighter and suitable for specific applications. Additionally, consider the environment where the ball screw will operate. Extreme temperatures or exposure to chemicals can influence material longevity.

Finally, don't overlook the type of lubrication. Different ball screws may require various lubrication types for optimal functioning. A poorly lubricated screw can wear out faster than expected. Reflect on your needs carefully. Sometimes, cheaper options may lead to long-term costs. Price isn't everything. Assess quality and compatibility before making a choice.

Maintenance and Care Tips for Extending Ball Screw Lifespan

Ball screws are vital components in many machines, requiring proper maintenance for longevity. Regular inspection is essential. Check for any signs of wear or damage. Dirt and debris can accumulate, affecting performance. Keeping these parts clean helps avoid costly replacements.

Lubrication is another critical aspect. Use the right type of lubricant to ensure smooth operation. Apply it regularly but not excessively. Over-lubrication can attract more dirt, causing problems. Monitor the lubrication levels closely.

Environmental factors also play a significant role in a ball screw’s lifespan. High temperatures can lead to degradation of materials. Protect these components from excessive heat and moisture. Consider using shields or covers if in such conditions. Proper care can significantly extend the lifespan of a ball screw. Remember, neglect can lead to failure, costing time and money.